Injection Molded Parts Made in the USA

CAD & DESIGN

We will take your sketch and turn it into a 3D CAD Drawing. This Drawing can be used for presentation, prototyping, and production. No drawing? No problem! Just tell us what you need.

RAPID PROTOTYPING

Using a 3D CAD model we can make a fully detailed prototype using an additive build process to test fit and function before commiting to the cost of full scale production.

INJECTION MOLD TOOLING

Using a CAD model we machine injection molds to make your parts. We eliminate unnecessary extras to provide you with a high-quality, low-cost method of production.

PART PRODUCTION

We can accommodate injection molded parts ranging from a few grams to sixteen ounces at our facility in Texas. We can make your parts in a variety of color and materials.

We will take your sketch, drawing, or idea and produce injection molded parts. For exact pricing for your particular part(s), contact our sales team.

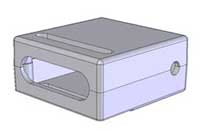

Epsilon Industries, Inc. is a manufacturer of simple injection molded parts. We turn your sketches, drawings, samples or 3D CAD files into usable production products for a fraction of conventional tooling costs. Our low prices are possible because we utilize high speed CNC machining centers to fabricate aluminum (or steel if required) inserts that work in our existing injection mold bases, eliminating much of the cost of producing a mold. We then mold as few or as many as required from your mold insert. We specialize in injection molded parts in many thermoplastic materials, including ABS, nylon, polypropylene, HIPS (High Impact Polystyrene), polycarbonate, and TPE (synthetic rubber) in the very shortest lead times. (2-8+ weeks depending on backlog). Expedited services (1-4 weeks) are also available.

You send us your idea and we send you injection molded parts.

Plus: You own the tooling!

For the most cost effective and timely response, we prefer a 3D CAD model of your part. If you do not already have a CAD model, then we can model your part as required. We will need a sketch, drawing, sample part or prototype.